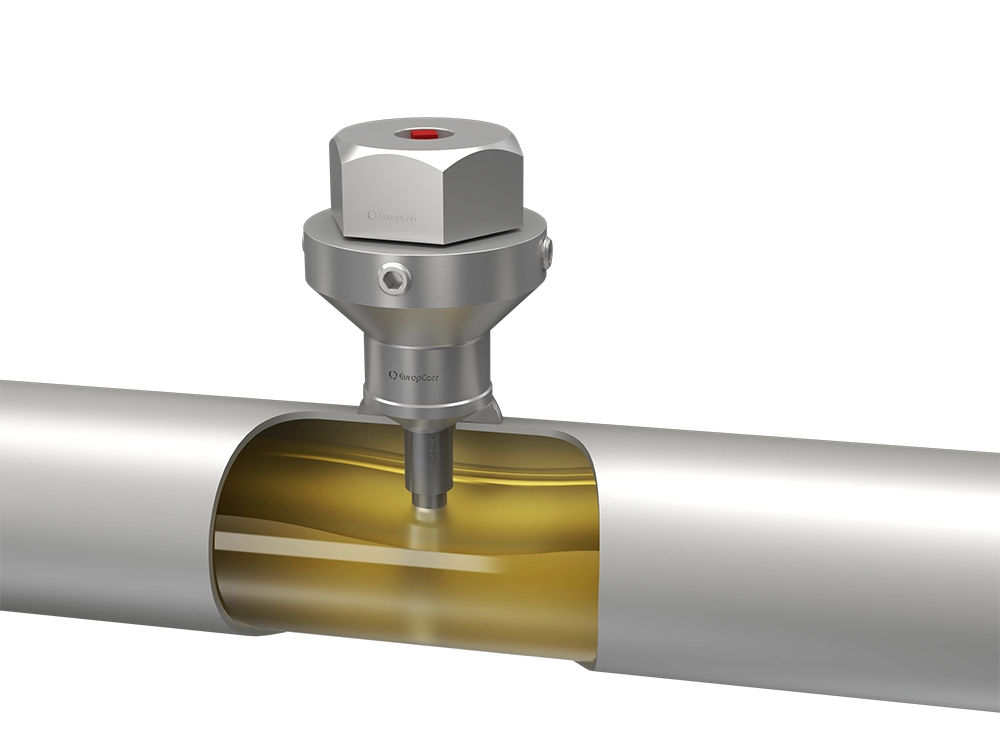

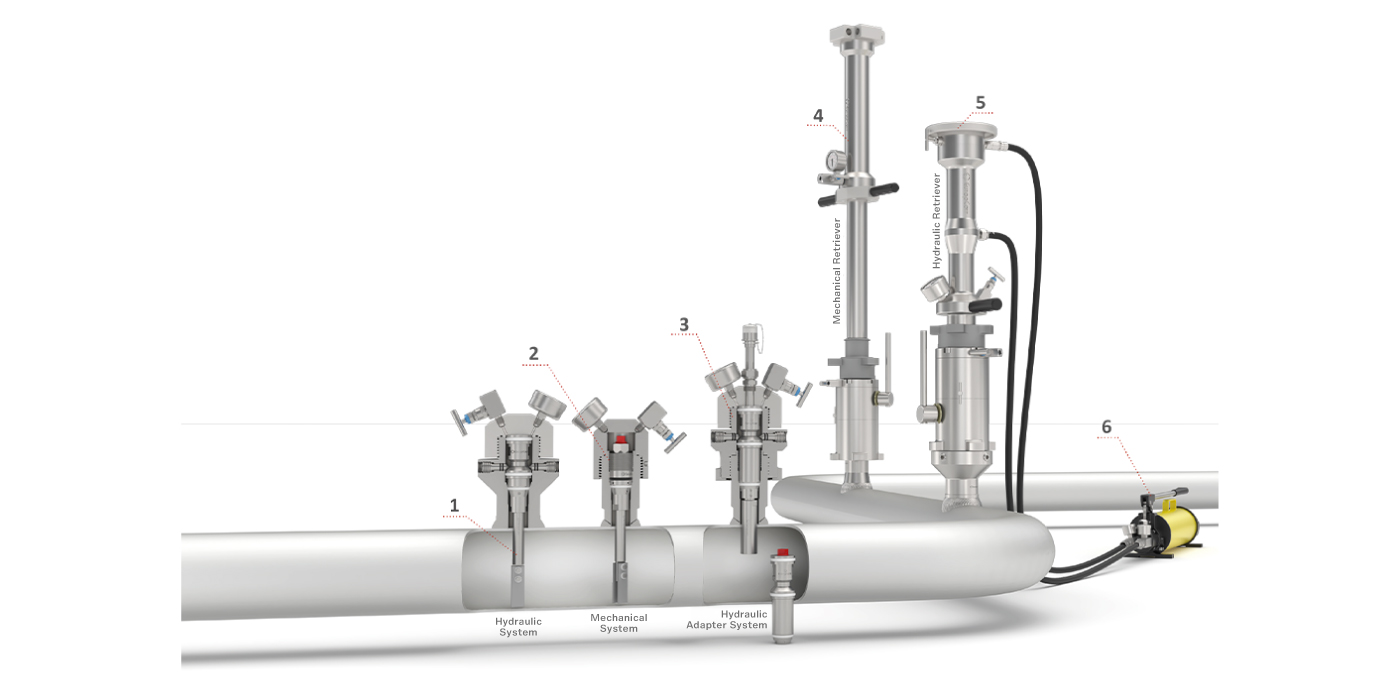

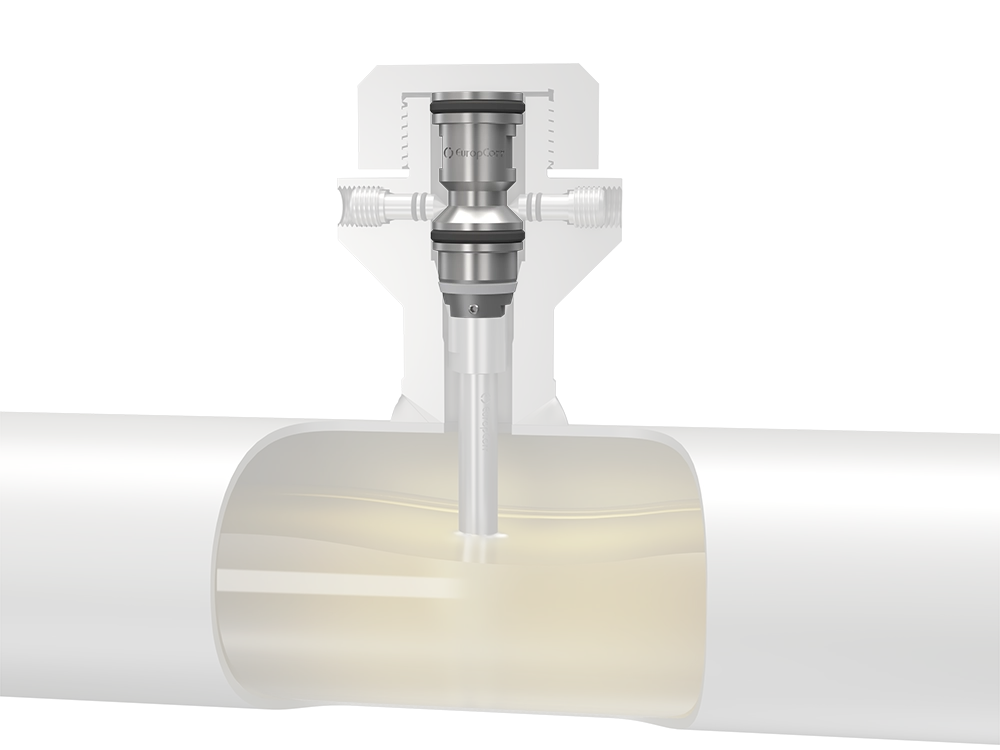

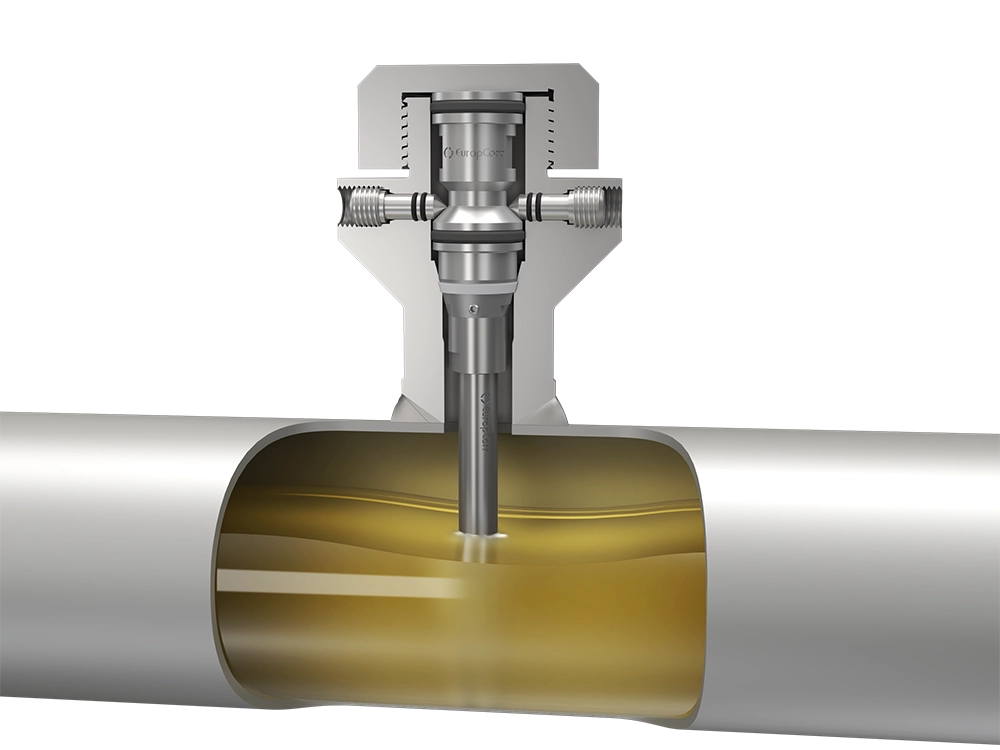

The Hydraulic Access System allows corrosion monitoring devices to access Oil and Gas facilities under full operating pressure.

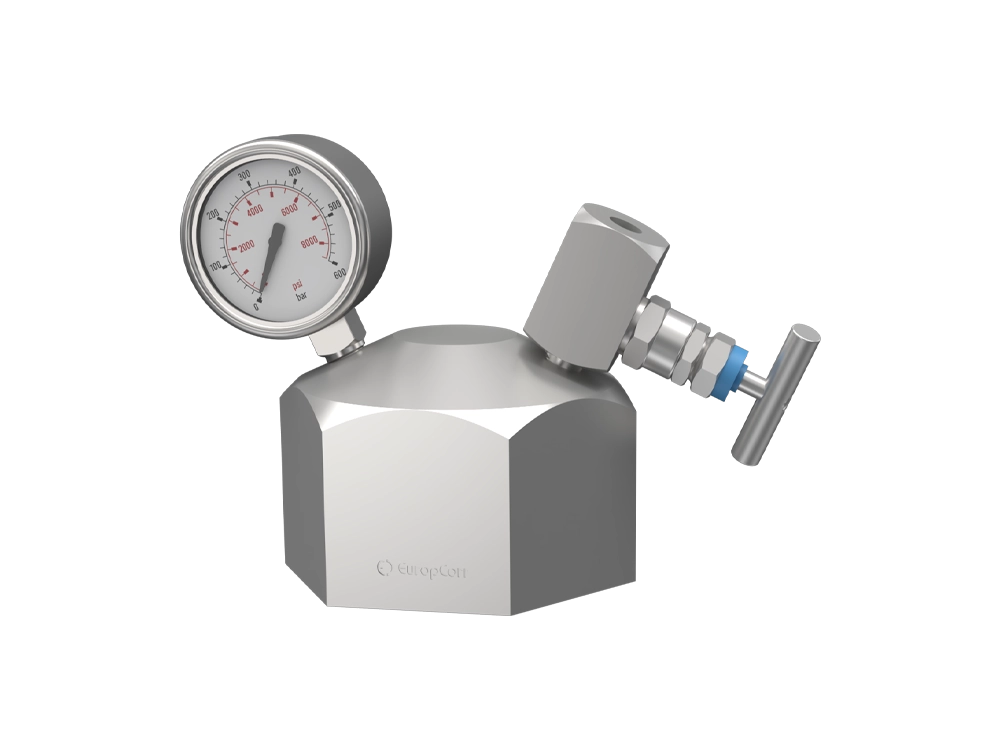

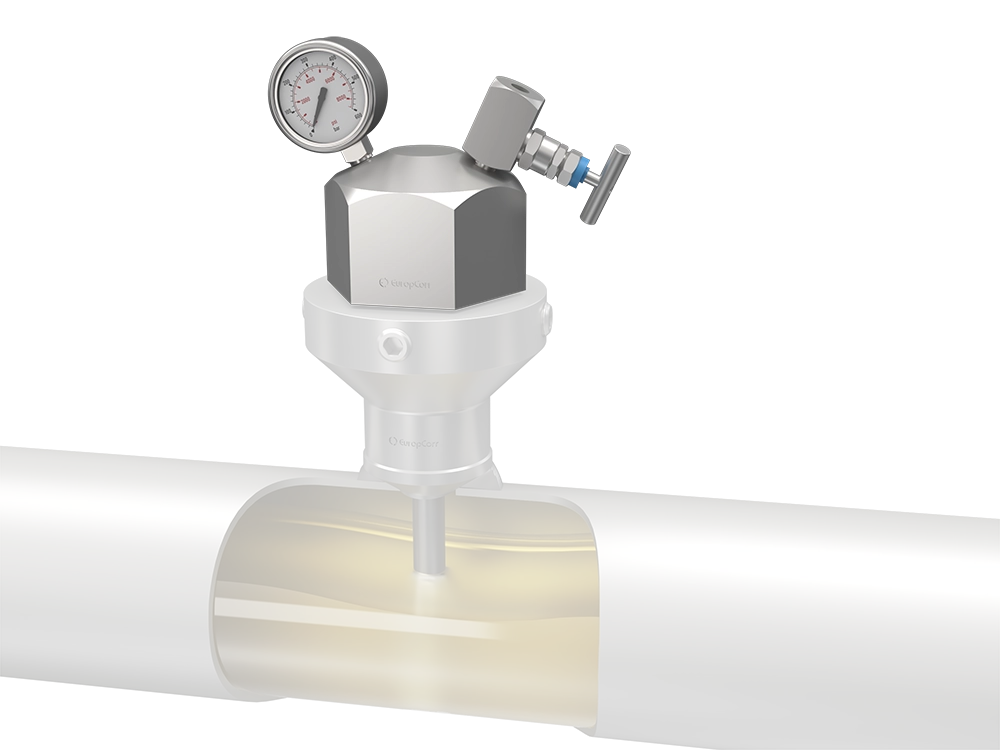

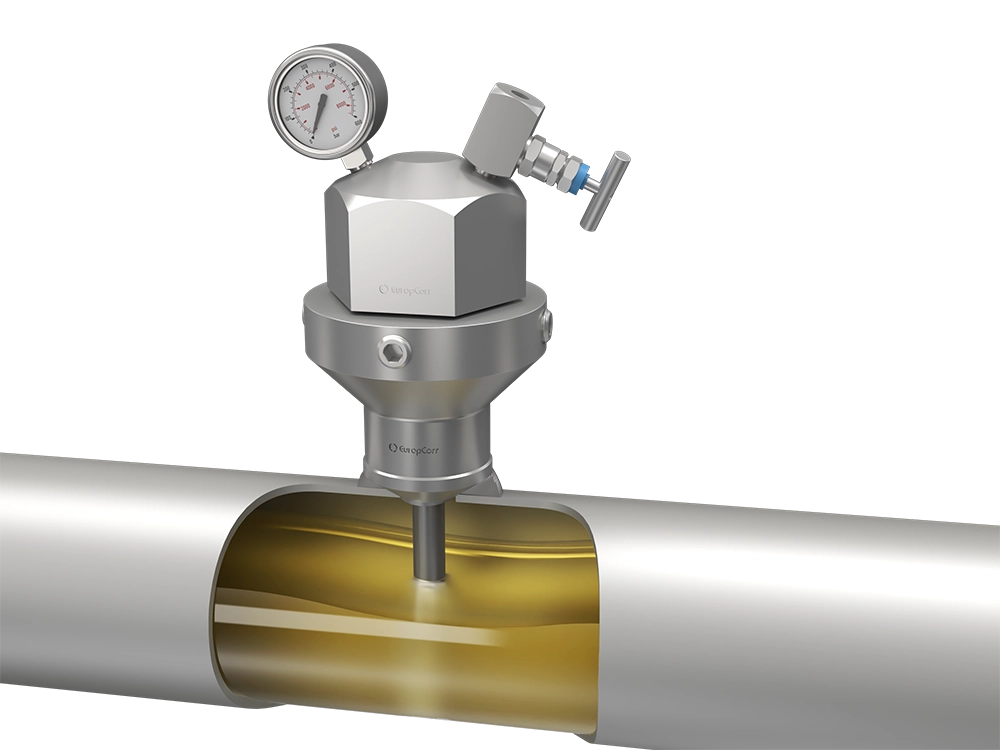

Hydraulic Access Fitting

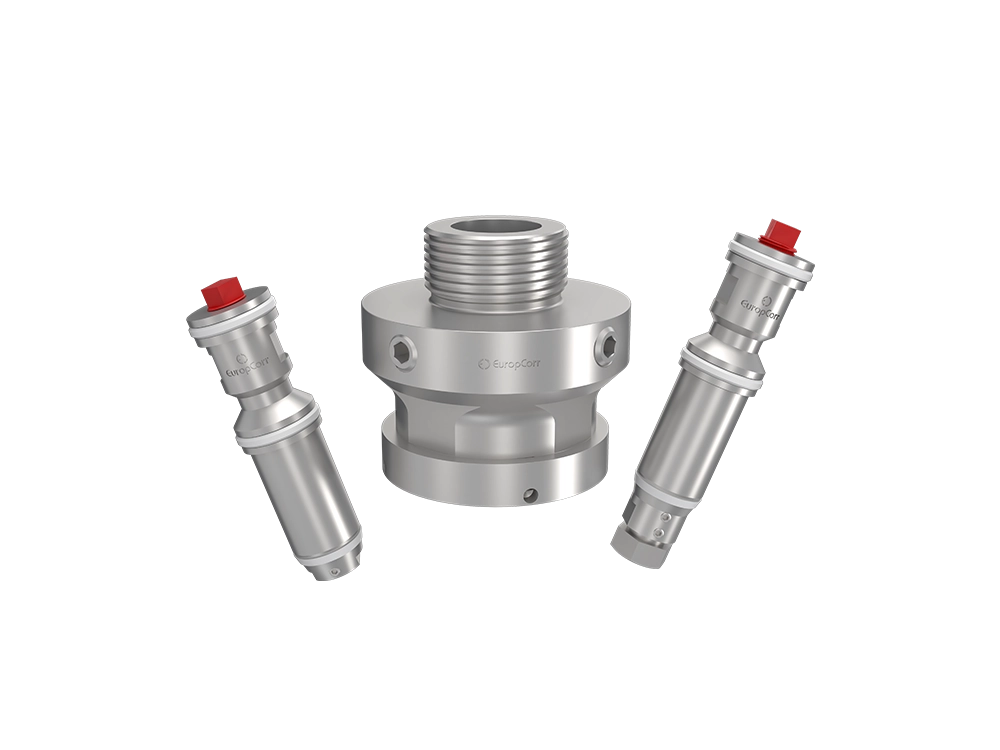

Hydraulic Plugs

Hydraulic Protective Covers

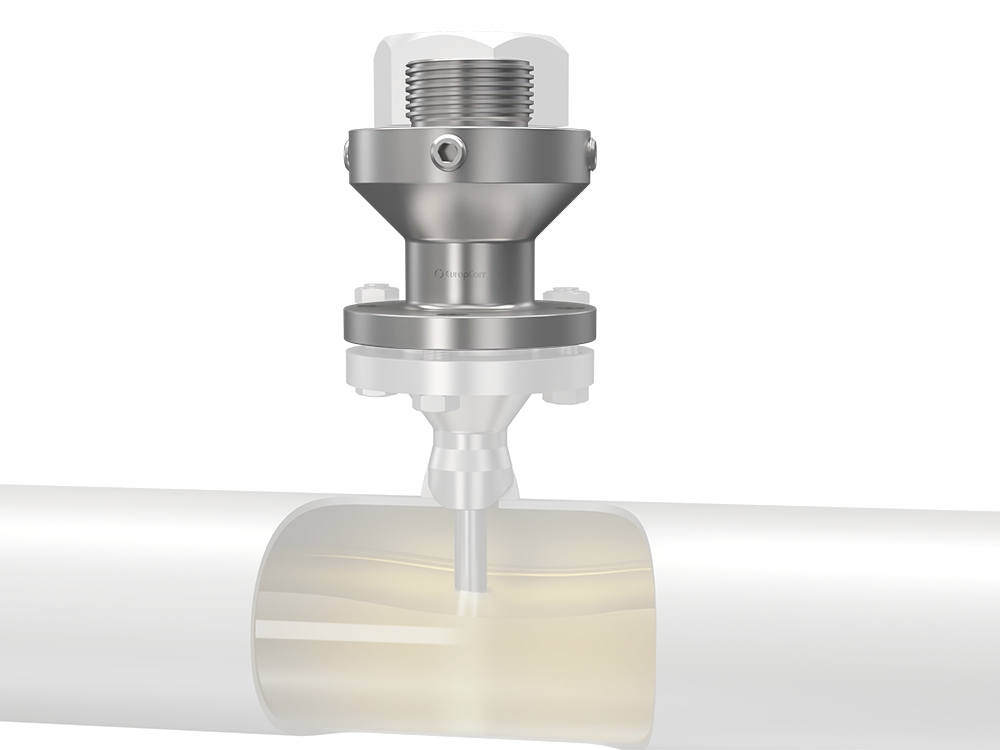

Adapter System

Hydraulic Access System

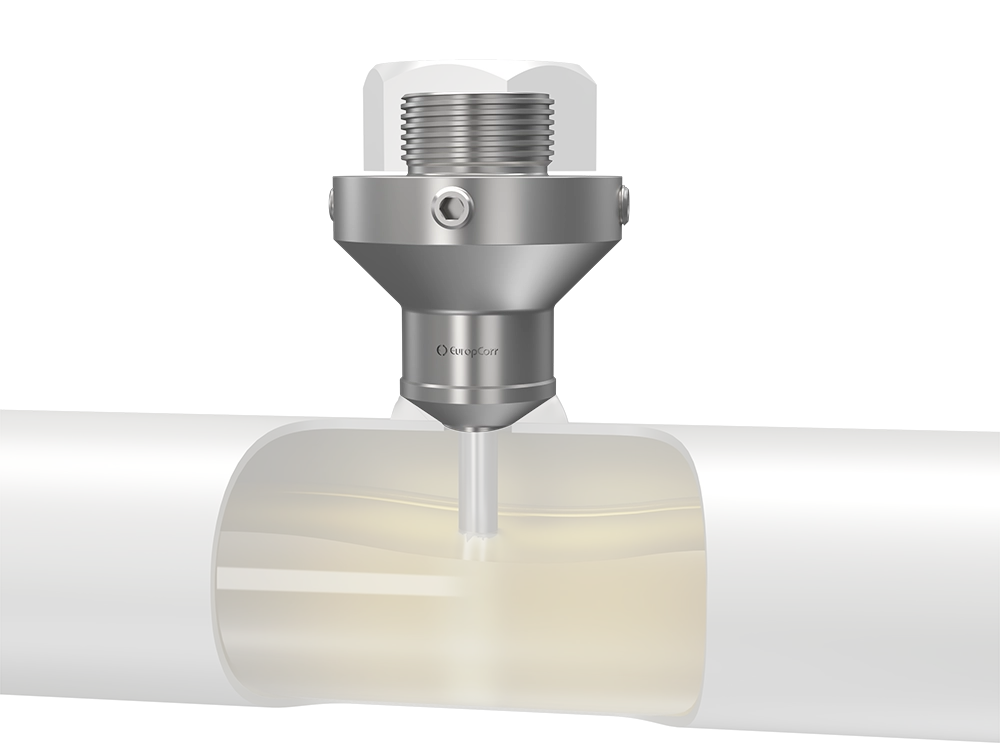

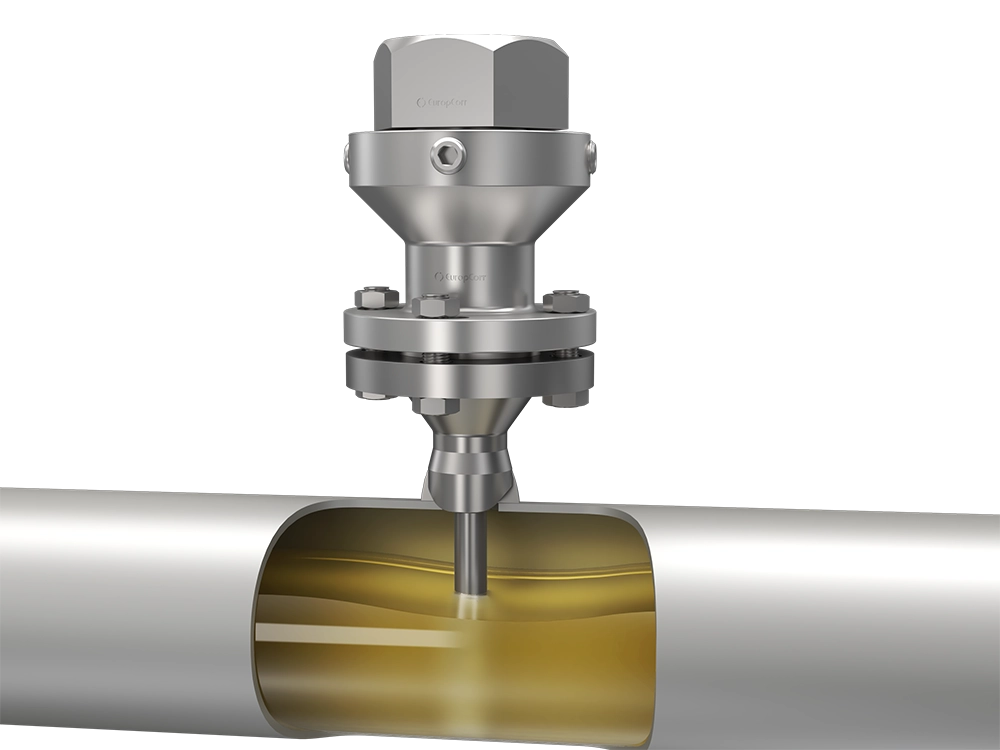

The Hydraulic Access Assembly permits corrosion monitoring devices to access to systems under full operating pressure, eliminating any need of system shut-down.

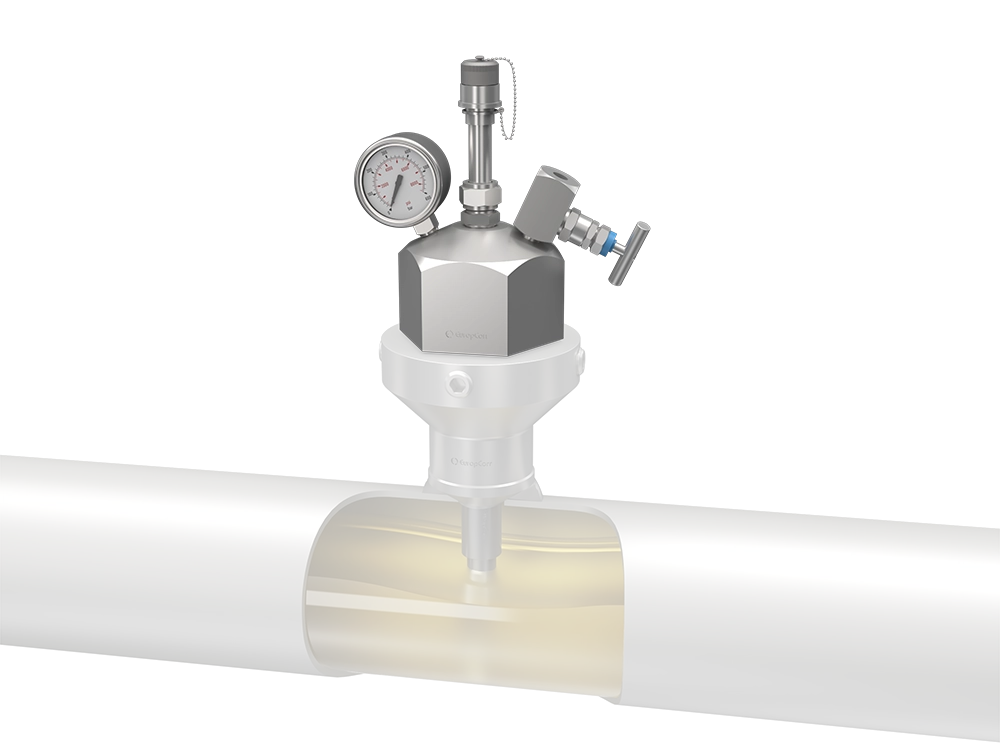

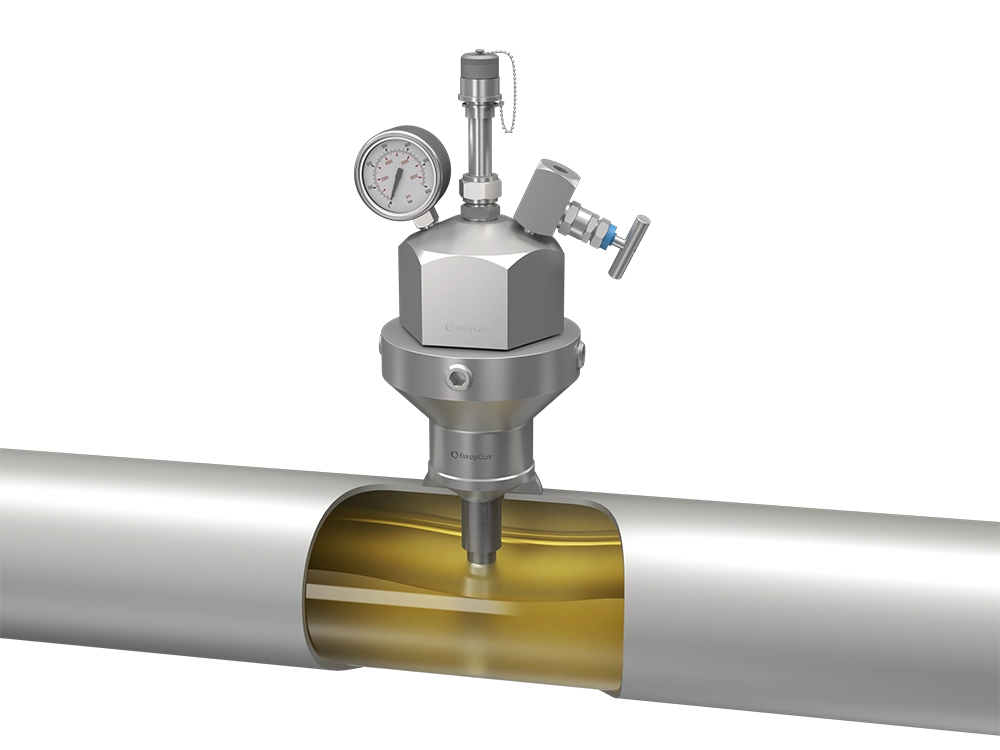

The Access Assembly allows safe and easy insertion and retrieval of devices by means of the Hydraulic Retrieval Tool Kit. Access System may be installed under system pressure with the use of EuropCorr Hot Tap Tool and can be mounted at any position of the pipeline that local operating conditions permit.

The assembly is composed by an Hydraulic Access Fitting, a Solid or Hollow Plug and a Heavy Duty Cover or a Pressure Retaining Cover. The components will depend on the applicable device: Weigth Loss & Special Coupons, Probes or Chemical Injection & Sampling Tubes.

In comparison with Mechanical System, Hydraulic configuration is safer and more reliable for installation and retrieving under full operating pressure.

In comparison with traditional Mechanical system, the Hydraulic configuration is the preferred technique for safe and easy installation and retrieving of monitoring devices such as Corrosion Coupons, Corrosion & Erosion Probes, Chemical Injection & Sampling.

The advantages

The system has important advantages from operational and safety point of view:

1. EASE OF ALIGNMENT

Precise alignment of tool and monitoring device in an access fitting of a pressurized system.

2. NO INTERNAL THREADS

Connections between hydraulic fitting and plug avoid galling and seized plugs caused by particles in the process.

3. COMPATIBILITY

Any mechanical system can be converted into hydraulic configuration through a suitable hydraulic adapter and a plug.

4. NO EXTERNAL MOVING PARTS

Increased safety to operators and assets.

5. SMALLER, SHORTER AND LIGHTER

Increased accessibility due to less operational space required.

6. OPERATED FROM DISTANCE

2 or 3 meters away from the high-pressure point via a hydraulic pump minimising the risk of exposure to operators.

![Hydraulic Hollow Plug [For Probes]](https://eurocorr.addlab.site/site/uploads/2024/06/1.Mechanical-fitting-Buttweld-1.webp)

![Hydraulic Hollow Plug [For Probes]](https://eurocorr.addlab.site/site/uploads/2024/06/2.Hydraulic-Hollow-Plug-Petrol-Assembly.webp)

![Hydraulic Hollow Plug [For Probes]](https://eurocorr.addlab.site/site/uploads/2024/06/3.Hydraulic-Hollow-Plug-Petrol-0.webp)

![Hydraulic Heavy Duty Cover for Coupon [and injection&sampling]](https://eurocorr.addlab.site/site/uploads/2024/06/1.Hydraulic-Heavy-Duty-Cover.webp)

![Hydraulic Heavy Duty Cover for Coupon [and injection&sampling]](https://eurocorr.addlab.site/site/uploads/2024/06/2.Hydraulic-Heavy-Duty-Cover-Petrol-Assembly.webp)

![Hydraulic Heavy Duty Cover for Coupon [and injection&sampling]](https://eurocorr.addlab.site/site/uploads/2024/06/3.Hydraulic-Heavy-Duty-Cover-Petrol-0.webp)