EuropCorr Italy is specialized in design, manufacturing, sales and after sales services of Corrosion Monitoring systems mainly for Petrochemical, Oil and Gas Industry.

Corrosion Monitoring

Corrosion is one of the most serious ageing mechanism impacting the equipment and assets of process facilities in Oil and Gas industry. The application of Corrosion Monitoring technical solutions allows to analyse the state of the pipeline or vessel giving us information about corrosivity, corrosion rate, process data and the effect of corrosion inhibitors.

Uncontrolled corrosion can:

Lead to severe safety and environmental hazards

Be costly in terms of interruption or stop in production processes and repair costs

Produce a risk of unexpected catastrophic failures

Produce environmental damage and potential harm to humans

Scientific approach

EuropCorr has an extensive knowledge about materials and their behaviour, monitoring and inspection methods, as well as instrumentation and information technology.

Extending plant & equipments lifetimes

Optimising maintenance programs

Preventing accidents & catastrophic failures

Increasing regularity and avaibility

Practical solutions

We work closely with our clients in technology development, field services, data management, planning inspection and monitoring programs.

Customizability

Flexibility

Reliability

Competitivity

EuropCorr Italy

We pride ourselves on providing customized solutions that exactly meet your requirements and exceed your expectations. Our commitment revolves around understanding your unique challenges and delivering services and products that perfectly align with your needs. We go beyond traditional approaches, leveraging innovation and creativity to provide the best solutions.

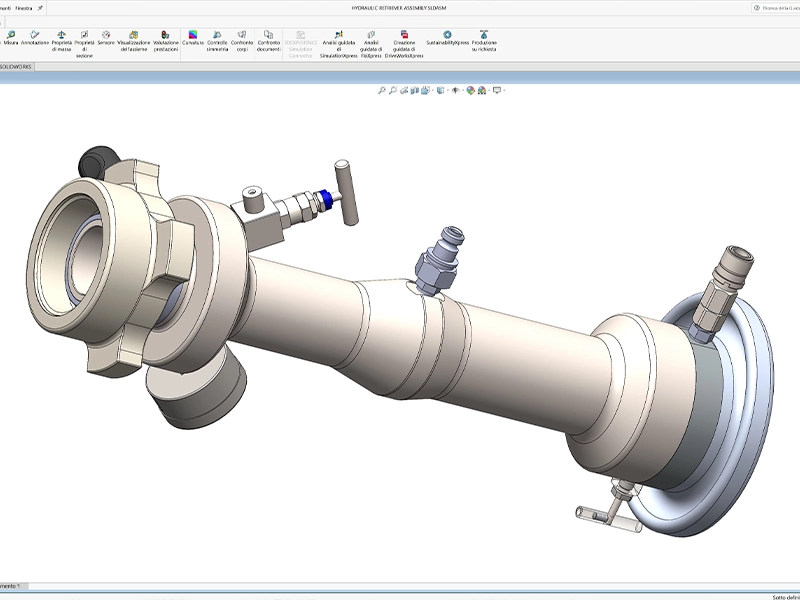

Engineering

Our quality management processes are informed by data analysis, enabling us to make informed decisions and drive continuous improvement.

- Corrosion and material selection

- Inspection & data management

- Certification

- Digital analysis

- Test performance (FAT, PMI, NDE, Pressure Test)

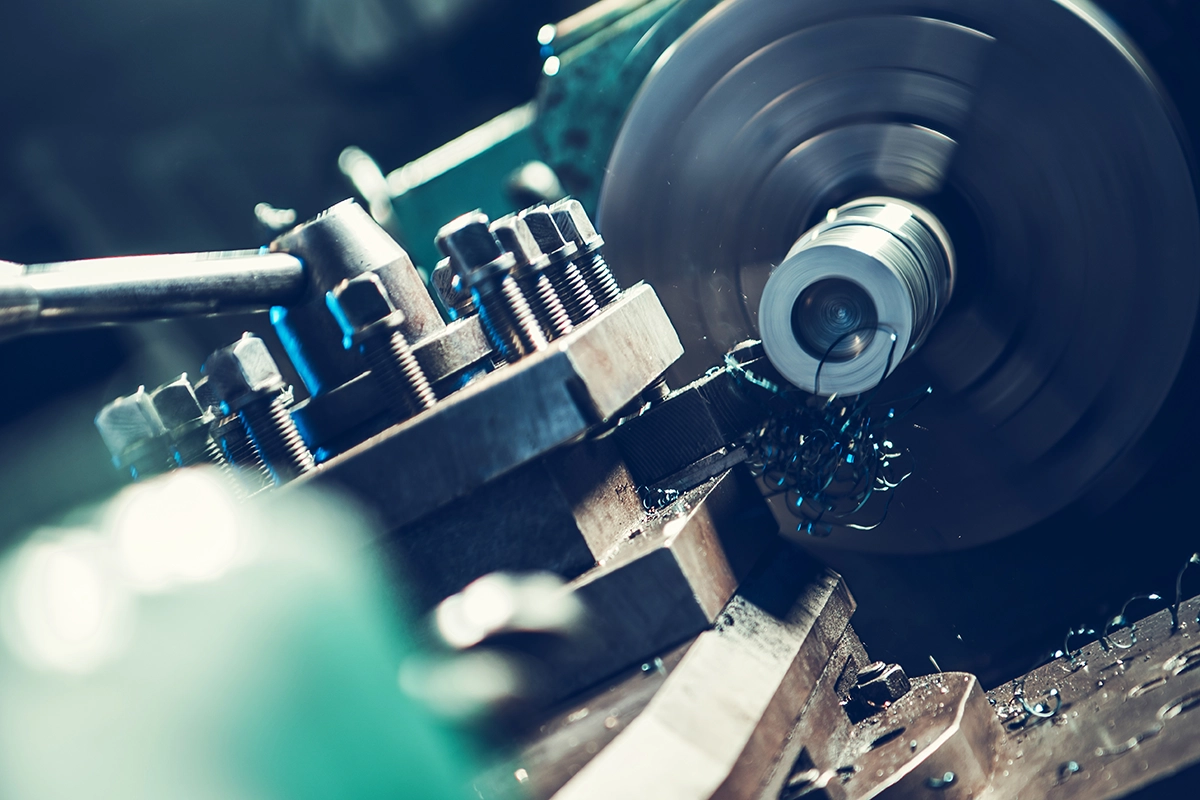

Manufacturing

We collaborate with industry partners and stakeholders to share best practices and collectively raise quality standards across the sector.

- Corrosion monitoring devices

- Instrumentation & Software

- Chemical Injection & Sampling devices

- Customized finishing of pieces

- Tailored production

Service & Training

Our workforce is trained and equipped with the necessary skills to maintain quality standards, identify improvement opportunities, train plant personnel and follow up services in the platforms.

- Corrosion site surveys

- Failure analysis

- Laboratory testing

- Field monitoring and inspection services

- Training courses

The Monitoring Cycle

For good maintenance of the installations it is important to have a cyclical analysis so the inhibition systems can be adapted to the chemical variations generated in the product.

There are two main methods for corrosion monitoring: Coupon and Probe.

Coupon is the classic type of Corrosion Monitoring device. It consists of introducing a piece of metal similar to the composition of pipeline for a certain period and then will be retrieved for visual inspection and laboratory analysis.

Probe is an electronic type device for a continuous monitoring. It is installed in the pipeline and the probe data can be collected by means of MaxiCorr portable instrument or MegaCorr data logger/transmitter without retrieving the probe.

Data collected from Corrosion Monitoring devices will be analysed using CorrTrack software, presenting corrosion related parameters through comprehensive and explanatory graphs and generating custom reports.

From data analysis the Client can optimise the use of inhibitors, inspection and maintenance programs to extend the plant and assets lifetime. The Corrosion Monitoring and analysing must continue in order to assure any changes can be detected and corrected on time.